Automation Blog

Automationware Makes Multi-Trolley System on Single Axis a Reality

In warehouses and logistics operations, there’s usually no better way to perform pick-and-place tasks than with a multi-axis automated system. Not only do multi-axis systems enable complex and precise movement of goods with excellent repeatability, they also optimize workflow to storage and retrieval operations. However, if your layout only allows a single axis, it can be difficult to handle multiple sorting tasks simultaneously. This blog post will describe how a single Automationware axis can support a multi-trolley picking system for logistics applications.

Sophisticated Multi-Axis System Management

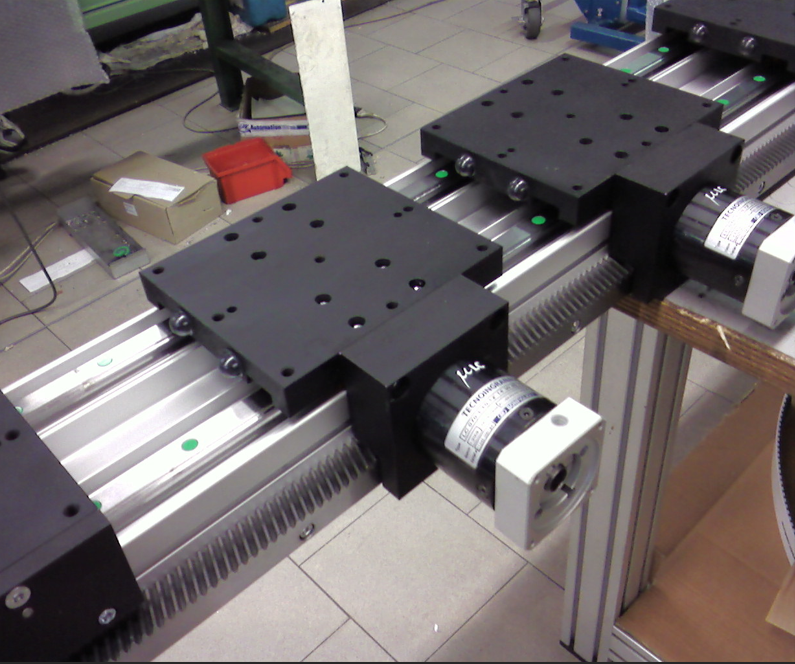

A single ML Series belt axis is at the heart of the multi-trolley system. These linear belt units come in either a cantilever-fixed-carriage and mobile profile, or a fixed-carriage and mobile profile on a double orthogonal guide. The axes are available in sizes 45, 60, 80, 90 and 120. Features include anodized aluminum construction, good loading capacity, high flexibility, low expansion and a positioning repeatability of 0.05 millimeter.

The trolleys incorporate AW precision sleds that are well-suited for fast pick-and-place systems. Featuring high operational reliability over time, these units are particularly desirable for high intensity work cycles and for small workpieces. In addition to the AW sliders, the trolleys also seamlessly integrate a guided pusher cylinder and a pneumatic picking system. The sleds are outfitted with a cutting-edge array of stereo cameras that both identify components and also pinpoint the objects’ optimal grasping points.

The completed system provides a warehouse operation with sophisticated multi-axis system management along with the following benefits:

- Increased picking and sorting accuracy.

- Improved efficiency.

- Reduced retrieval times for optimal throughput.

- Less reliance on human labor and a reduction in associated safety issues.

This innovative solution is a perfect example of how Automationware’s actuator platform and modular products successfully address a common challenge to enhance productivity and efficiency in the logistics sector.

Automationware’s linear axes portfolio and sliders are available from our U.S. distribution partner, IKO International. Please visit www.automationwareusa.com, or contact IKO at ikoaw_usa@ikonet.co.jp for more information.