Automation Blog

Electric Grippers Help Pharmaceutical Cobots Reach Productivity Goals

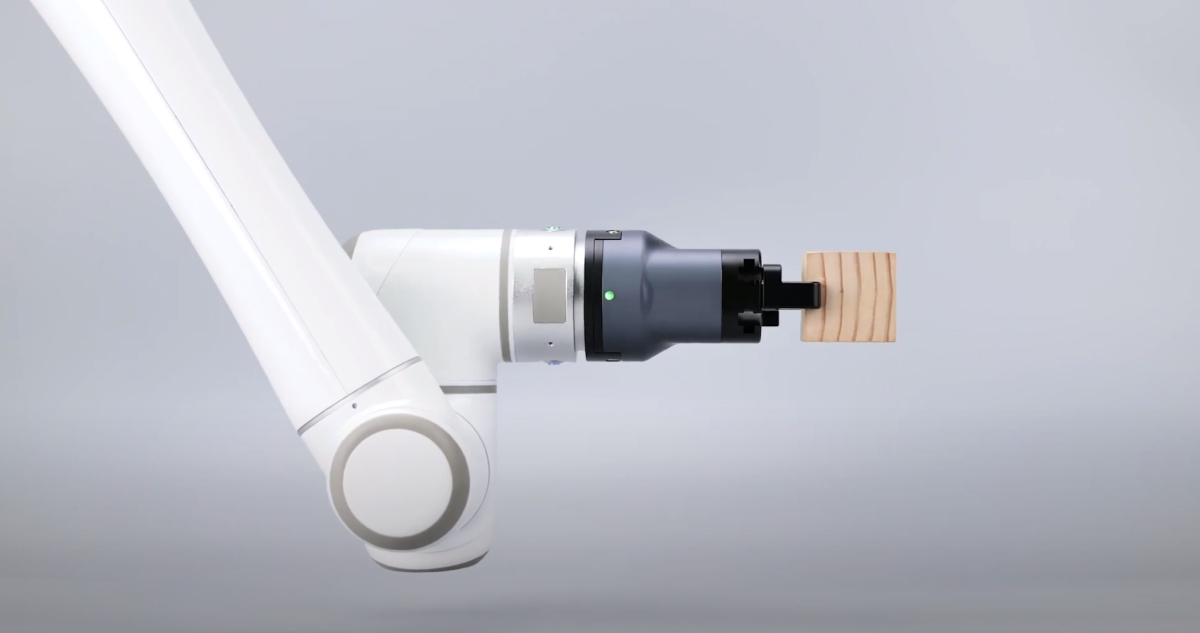

As the pharmaceutical sector rapidly transforms the way medicines are discovered, manufactured and packaged, cobots are playing an integral role in the industry’s ability to meet aggressive productivity goals. In an industry that emphasizes accuracy, efficiency and safety, it’s important to select a gripper that delivers precise control of gripping force, speed and positioning, operates efficiently, and — above all — is suitable for clean environments. This blog post will provide an overview of some common pharmaceutical applications that often use electric grippers along with the benefits these end effectors provide.

In a previous blog post, we detailed several advantages that electric grippers provide versus conventional grippers, including high precision and programmable control, exceptional flexibility, high speeds and short cycle times, as well as power and cost savings. They’re also a cleaner option than air-driven grippers, which can otherwise leak contaminants into the air. Here are some pharmaceutical tasks that are typically carried out by cobots outfitted with electric grippers:

- Handling and dispensing. Programmable cobots are able to differentiate pills by size and weight as well as scan labels. Electric grippers with integrated controllers seamlessly integrate with these cobots, giving them the dexterity to handle various pills with the right gripping force, speed and positioning accuracy to avoid damaging delicate products and objects.

- Assembly. Not only do cobots enhance production efficiency, they can be programmed to work in various production areas, making them exceptionally versatile. This versatility is especially desirable in small-batch manufacturing operations that adapt to changing needs. Parallel grippers with a slim design — such as our PGE and CGE Series — are particularly attractive for small and medium-sized parts assembly.

- Packaging and palletizing. Whether used for picking, lifting or stacking tasks, our PGI and CGU Series parallel-type grippers as well as RGI Series servo rotating grippers help cobots manipulate various-sized objects in a host of pharmaceutical packaging processes.

- Laboratory automation. Clean, hygienic electric grippers can handle a variety of laboratory objects such as vials and test tubes, probes and microplates, to name a few.

A Potent Range of Electric Grippers for Pharmaceutical Manufacturing

At Automationware, we have a wide and varied portfolio of types including parallel, collaborative parallel, centric, servo rotating and linkage units. Our electric gripper lineup supports many commercially available cobots and provides the precise manipulation that pharmaceutical applications demand. Features include integrated drive controllers, precise and adjustable gripping force, short opening and closing times, as well as intelligent feedback to make gripping process monitoring easy. Many units also feature self-locking functionality for safety, and long-strokes and adaptive gripping capabilities are also available.

IKO is the U.S. distribution partner for AutomationWare. Visit www.automationwareusa.com, or contact IKO at ikoaw_usa@ikonet.co.jp for more information.